Microfluidic flow control is an incredibly important component in the development and operation of any microfluidic device. It permits the accurate manipulation and delivery of small volumes of liquid, which enables a vast array of applications in drug research, lab-on-a-chip systems, point-of-care diagnostics, and more. In this blog post, we will cover two of the main ways to control microfluidic flow: popular and widely used methods like peristaltic pumps, pressure controllers, and syringe pumps; as well as miniature pumps which are becoming increasingly used in microfluidics.

The most used methods for microfluidic flow control

1- Flow control with a syringe pump or a volumetric pump in microfluidics

Syringe pumps are one of the most common methods used to control microfluidic flows. These versatile and reliable pumps are based on a mechanical system usually operated by an electric motor which pushes a syringe plunger at a fixed rate.

Incorporating a stepper motor and plunger, they are capable of both push-in infusion and pull-out withdrawal, making them a very valuable tool in a laboratory. Depending on the application, syringe pumps can be designed to accommodate a large number of syringes.

These devices are capable of operating with very accurate and precise volumetric flow rates, ranging from milliliters to picoliters. With their flexibility and accuracy, syringe pumps can be a great asset in any laboratory setting.

On the other hand, they may have slow response times and can fail due to excessive pressures or clogging of channels/tubes. Furthermore, their dispense volume is limited by the size of the syringe pump, making them difficult to use them for long-term experiments.

The greatest advantage of syringe pumps is their ease of use. Even with little expertise, syringe pumps can be set up and pumping fluid within minutes. With programmable syringe pumps, users can go beyond simple infusion and withdrawal operations and create customized pumping methods that consist of simple to complex flow profiles, adding even more versatility to an already tried and true flow control method.

Overall, syringe pumps are great tools to control microfluidic flows, but they should be used with caution and a thorough understanding of their strengths and weaknesses. Other methods such as volumetric control may also be considered when looking to precisely control microfluidic flows.

💪 Strengths

- Fast and easy setup for microfluidic experiments.

- Accuracy of 0.25% max with near pulseless syringe pumps

- Allows user to define the total volume of fluid used in an experiment.

- High pressures of several hundred bar can be generated with syringe pumps.

- The mean flow rate remains constant even with varying microfluidic resistance in an experiment (unless the pump stalls due to excessive pressures).

😢 Weaknesses

- Flow rate response times can be of severals seconds depending on the microfluidic resistance.

- The flow rate when switching from one flow rate to another cannot be known without a flow sensors.

- Excessive microfluidic resistance (such as channel or tubing clogging) can lead to a pressure buildup and the eventual failure of the syringe pump.

- Fluid dispensing volume is limited by the volume of the syringe, complicating things for long-term experiments.

💡 A few tips to use a syringe pump or a volumetric pump

Syringe pumps are an invaluable tool in many research laboratories, and with proper care and maintenance they can provide years of reliable service. By following these tips you will be able to make sure that your syringe pump remains a reliable part of your laboratory equipment for years to come.- Before using a syringe pump, always check that it is compatible with the type of fluid being used and that all connections are properly secured.

- Your syringe pump must be regularly calibrated to ensure precise control over the flow rate and volume of fluids. This can be done by verifying that readings on the pump’s display match up with a measurement taken with a graduated cylinder or other reference measuring device.

- Make sure you are using the correct size of syringe for the pump and that the plunger is free of obstructions.

- After your experiment, ensure that all connections are properly disconnected and stored away for safekeeping.

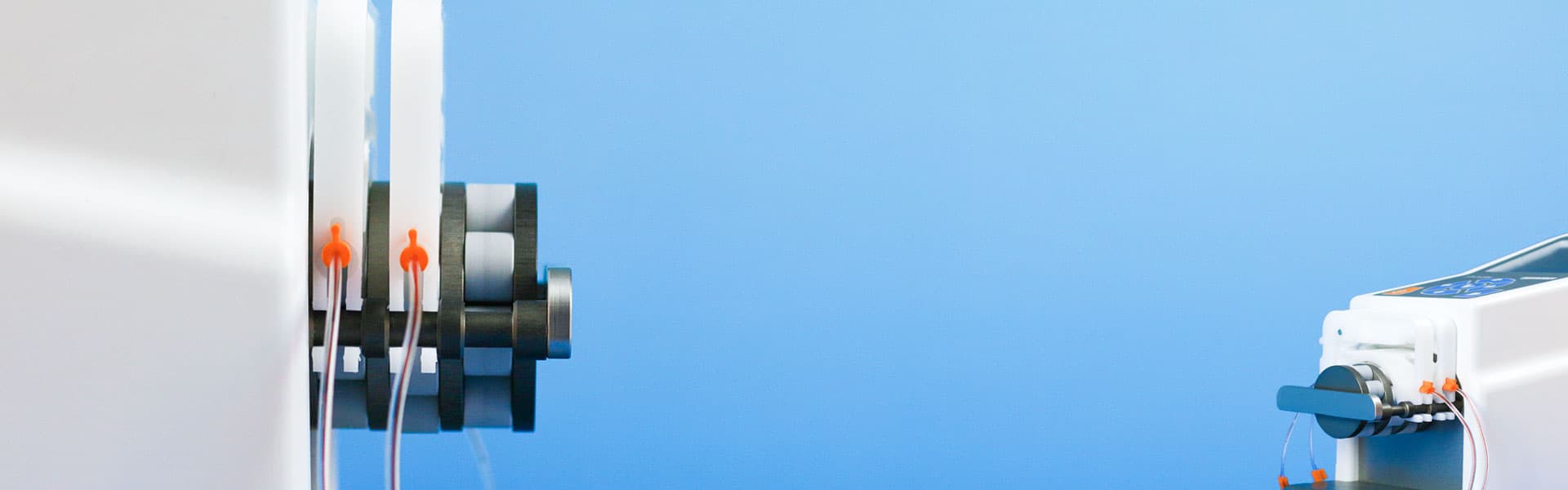

2- Flow control with a peristaltic pump or a hose pump in microfluidics

Peristaltic pumps are a versatile, efficient and reliable type of pump that offer precise flow control. By using a flexible tube inside the pump head, pressure is applied to the liquid within, causing it to be squeezed through the length of the tubing and controlling its speed. This makes peristaltic pumps ideal for applications such as dispensing, dosing and transferring small volumes of liquid. You can check our Comprehensive Guide to better understand these concepts.

Peristaltic pumps are an ideal solution for long-term experiments, as they can continuously circulate fluids without any contact between the pumping mechanism and the medium being pumped. This is especially beneficial in applications where contamination or hazardous media are involved, as it eliminates the risk of any contacts.

Whilst this technology has many benefits, it also has its drawbacks. It is important to remember the strengths and weaknesses of peristaltic pumps when making your choice.

💪 Strengths

- Easy set-up.

- Continuous circulation of fluid allows infinite dispensing volume.

- Recirculation of the same sample is possible (in a closed loop system).

- Can be independently operated in parallel.

- Well adapted to pumping high-viscosity fluids.

😢Weaknesses

- High oscillations in the flow rate.

- Significant vibrations and noise produced.

- Tubing must occasionally be replaced.

- Peristaltic pumps cannot reach very low flow rates (less than 1 µL/min).

- Usually less accurate than syringe pumps and pressure controllers.

💡 A few tips to use a peristaltic pump

- Before turning on the power, make sure that everything is securely hooked up.

- Use the correct tubing size for your application. The inner diameter of your tube will impact the flow rate you can reach.

- Inspect your tubing regularly for signs of wear or damage. Replace worn tubing to prevent leakage

3- Flow control with a pressure controller in microfluidics

Microfluidic flow control technologies are often used to move small volumes of fluids in a precise and efficient manner. Pressure is one of the main tools used to control microfluidic flow, and there are several ways to utilize it.

The simplest way is to use hydrostatic pressure, which works by setting the inlet reservoir higher than the outlet reservoir to allow gravity to push the fluid from the inlet to the outlet, like a water tower. Another way is using pressure controllers, which pressurize sample reservoirs to control the pressure drop between the inlet and outlet of the microfluidic system.

Pressure controllers offer settling times of 40 ms and stability of 0.1% CV on measured values.

When pressure is applied to fluids in a sealed container with an outlet, the fluid will move due to the pressure differencial and follow the equation: ΔP = Q x R (with Q = flow rate; ΔP = pressure difference; and R = resistance to flow). This means that the resulting flow is dependant of the apply pressure and the resistance of the system. The resistance is therefore particularly important since it depends on the viscosity of the fluid used as well as the geometry of the channels. This is a parameter that is not really taken into account when using a syringe pump for example.

However, pressure pumps do have some disadvantages, including being limited to 8 bars and the potential for backflow due to flow switches with multiple entry points.

💪 Strengths

- Pressure driven flow ensures pulseless flow.

- Large sample volumes of up to several liters can be used.

- Fast response time of ~40 ms (for the OB1 from Elveflow).

- Can control fluids in dead-end channels without risk of system failure.

- Flow rate control can easily be achieved with flow sensor feedback.

- Well adapted to pumping high-viscosity fluids.

😢 Weaknesses

- High pressures (exceeding ~8 bar) are not possible with pressure controllers.

- Pressure imbalances can result in back flows in the system. Either careful pressure control or valves can be employed to counter this.

- High cost compared to other flow control methods.

- Recirculation of the same sample is impossible with only a pressure controller.

- Fluid dispensing volume is limited by the volume of the reservoirs, complicating things for long term experiments.

💡 A few tips to use a pressure controller

- Equip your setup with a Microfluidic Backflow Blocker to prevents backflows into your pressure controller.

- Couple your pressure controller with a flow sensor to create a feedback loop and easily adjust the pressure until the desired flow rate is achieved.

- Do not use an oversized reservoirs in your experiment.

- Use a specific reservoir if you are planning to use high pressure in your setup.

READY TO OPTIMIZE YOUR FLUID SYSTEMS?

Explore how our pressure controllers optimize fluid dynamics for better performance!Miniature pumps: An increasingly popular method for flow control in microfluidics.

The growing interest in miniature pumps is due to the advantages they offer in microfluidics. Miniature pumps are significantly smaller than traditional pumps, allowing for more compact designs that can fit into tighter spaces. They can also have higher accuracy when dosing and controlling small volumes of fluids, as well as lower manufacturing costs. This makes them ideal for use in research and industrial applications. Furthermore, the improved control of small fluid volumes enables advanced microfluidic processes and protocols to be performed with greater precision. This emphasizes the importance of miniature pumps for current and future microfluidic research.

For these reasons, micropumps are poised to play an increasingly important role in microfluidics in the years to come.

1- Flow control with a piezoelectric pump in microfluidics

The Piezoelectric Pump is a remarkably thin, compact and lightweight diaphragm micro-pump that has been designed with space-conscious built-in applications in mind. It is an incredibly convenient pump for those limited by tight spaces without sacrificing on the power of pumping capabilities. With its unique design, it is capable of providing an efficient and effective pumping solution.

The functional principle of piezo micropumps is based on a combination of a piezoelectric diaphragm and passive check valves.

By applying a voltage to the piezo ceramic which is mounted on a coated brass membrane, it causes the diaphragm to deform and create a down stroke. This in turn displaces the medium out of the pump chamber below. The check valves on either side of the chamber help direct and control the flow direction.

💪 Strengths

- Cost-effective.

- Rapid dynamic response.

- High reliability.

- Works with open reservoirs, like a peristaltic pump

- Light weight.

😢 Weaknesses

- Low back pressure allowed (+/- 600 mbar).

- Limited by the viscosity of the fluid.

- Have to be used with an external flow-sensor.

- Low chemical compatibility with organic solvents.

- The flow is not as pulseless as with a syringe pump or pressure controller.

💡 A few tips to use a piezoelectric pump

- Make sure that the fluid reservoir is filled to the recommended levels before running the pump. This can help ensure smooth operation and prevent cavitation from occurring.

- Make sure the inlet and outlet are not blocked. Pressure build-up can damage your pump. For additional safety, you can use a pressure sensor for Bartels pumps to monitor the pressure.

- Use a damper to reduce the pulsatility of the flow.

- You can use a flow sensor to monitor your flow-rate.

2- Flow control with a Micro Annular Gear Pump in microfluidics

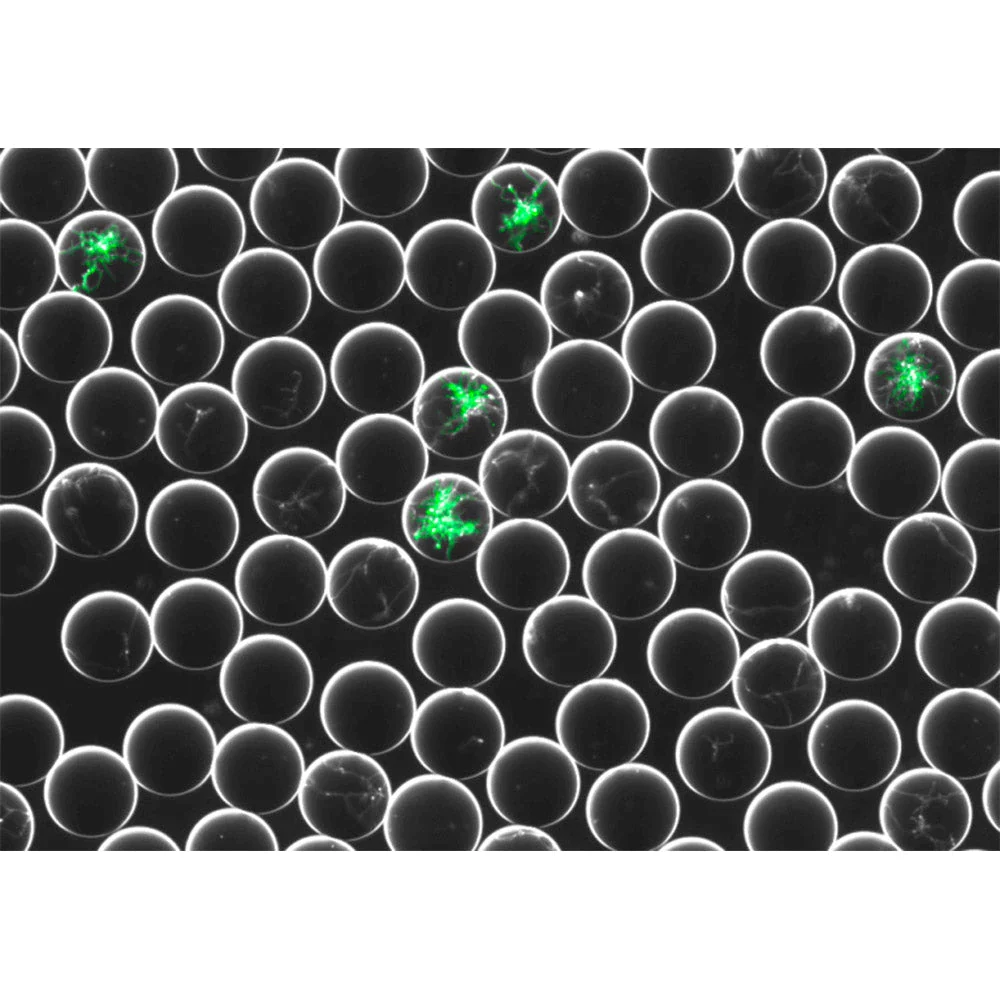

A micro annular pump, also known as a gerotor or trochoid pump, is a type of internal gear pump that consists of inner and outer gears assembled eccentrically within the pump casing. When the inner gear is rotated, it turns the outer gear in the same direction. The slight differences between the number of teeth on each gear and their centre points mean that the volume of the gaps between them changes with every cycle. Thanks to the tight tolerances between the gears, this allows the pump to create a suction force at its inlet and prevents liquid from leaking out on the discharge side.

What makes micro annular pumps so attractive is their small size and compact design. That, combined with their adjustable flow rate that is directly dependent on the speed of their gears’ rotation, makes them an ideal choice for precise dosing. Plus, incremental rotation of the gears makes it easy to control the amount of liquid dispensed.

💪 Strengths

- Highly compact and simple devices, ideal for applications that require accurate delivery or metering of liquids.

- Open reservoirs: easy recirculation

- Low pulsatility (comparable to a syringe pump)

😢 Weaknesses

- Cannot go to flow rates lower than a few µL/min.

- Many parameters must be taken into account to make sure this suits your needs.

- Micro annular pumps have tight tolerances, making them susceptible to wear from abrasive liquids and solids. You will need to filter your solution before using it.

- This is not appropriate for cellular or particle-laden media.

💡 A few tips to use a microannular gear pump

- Make sure to keep the gear pump’s inlet and outlet ports clean to ensure proper flow. Pressure can easily build up and damage the pump.

- Always filter your liquids to avoid any damage to the gears.

- Make sure your solution is compatible with the gear pump rotor.

- Make sure the pump is above what is downstream or use a check valve to avoid any backflow. Or use a check valve.