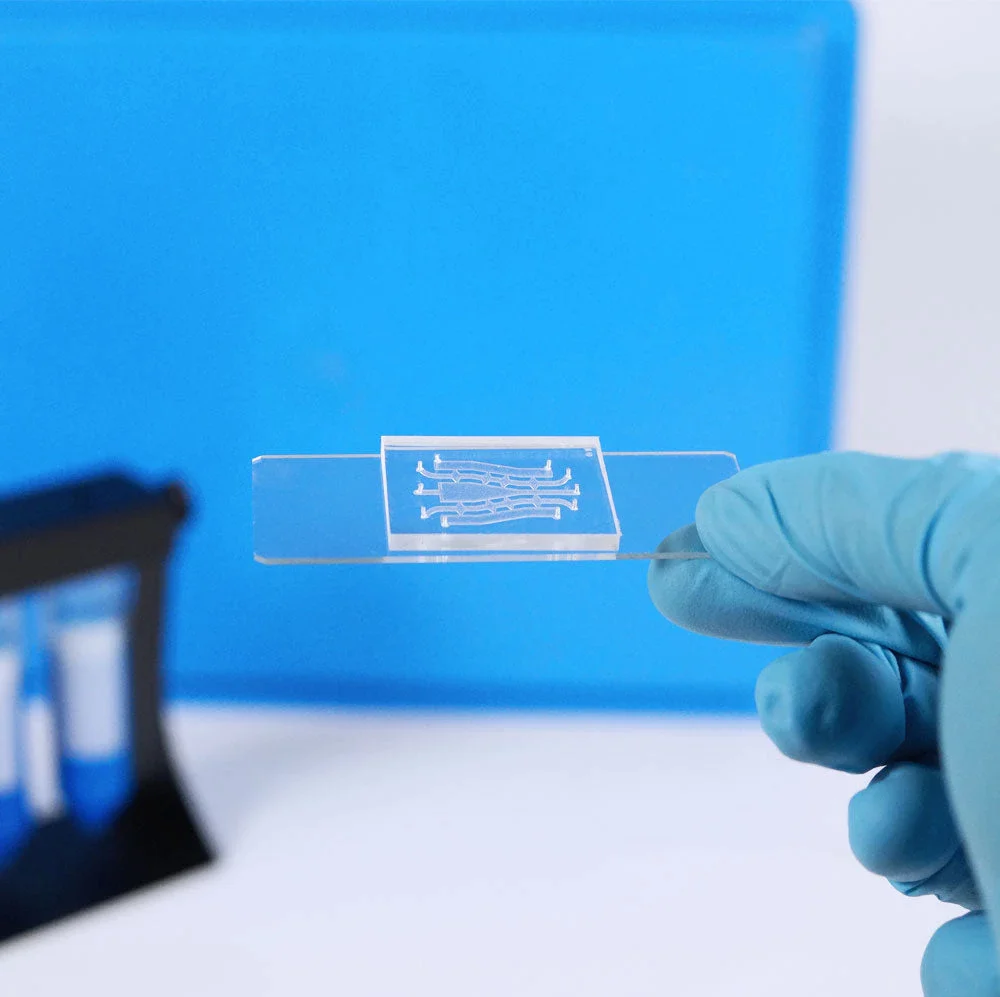

Generally, hydrogels have been utilized as scaffold materials for the immobilization of cells in a microfluidic chip. Different strategies have been employed for the preparation of three-dimensional cell-hydrogel scaffolds. In this review, we discuss the main hydrogels that can be used in microfluidic systems and the methods used to create these scaffolds.

The main types of hydrogels

Alginate

Alginate is distributed widely in the cell walls of brown algae that is hydrophilic and forms a viscous gum when hydrated. In our case, alginates-algae-derived polysaccharides-form into the hydrogel can potentially be used for the synthesis of cell scaffold after the addition of calcium ions. Alginate is known to form reticulated structures called egg box structures in the presence of divalent metal cations such as calcium and magnesium. This hydrogel has several interesting characteristics, such as its high absorption capacity and biocompatibility, which are highly sought-after characteristics for clinical or biological applications. Moreover, the chemical modification of alginate by introducing functional groups into the carboxylic group makes it a smart material due to its reactivity to light, temperature, and hypersonic disturbances. The adhesion of alginate to cells can also be improved by the introduction of cell adhesion molecules in the side chains. Alginate has been exploited in the form of isotropic hydrogels.

Matrigel

The extracellular matrix of the cells is composed of a large part of collagen. Thus, while 3D culture has been revolutionizing the world of research for several years now, the possibility of recreating a 3D matrix has also gained ground. In this way, the Corning brand Matrigel® allows this feat. Indeed, the Matrigel®, which is composed mainly of collagen, allows the cells to keep their original morphology in a 3D scaffolding providing an appropriate environment to maintain the functional phenotype of these same cells.

Gelatin

The melting temperature of the gelatine is 40°C. Above this temperature, the gelatine chains are in coil form. The gelatine solution is in a viscous liquid phase, called the “sol” phase. Below 30°C, a renaturation of the native triple helix structure occurs, and the chains again form a three-dimensional network of helical segments connected by single-stranded coils. The gelatin then behaves elastically and is in the so-called “gel” phase. The transition between the coils and the helices is completely reversible and the transition from one phase to the other is called the “sol-gel” transition. For all these physical properties, gelatine is, like the hydrogels presented above, a material of choice for cell encapsulation.

Mixture of hydrogels

Although each of these hydrogels has its own characteristics and can be used individually to encapsulate the cells, the best solution is a mixture of hydrogels. In microfluidics, it is not uncommon to combine alginate with matrigel, for example to gel droplets containing cells. Indeed, this association of hygrogel allows in particular the increase of cellular spreading [de Guzman et al. 2008 J. Microencapsul].

Methods to create 3D scaffold in microfluidics

The mechanism for gelling a hydrogel can sometimes be tricky, making the preparation and handling of gels complicated. Actually, it exists 3 main methods to provide a 3D scaffold in microfluidics: the forced-floating method, the hanging drop method, and the agitation-based method. In the following table, you can find all advantages and disadvantages of these 3 methods.

| Method | Advantages | Disadvantages |

| forced-floating approach: preventing cells from attaching to their surface | -Relatively simple – Inexpensive -Suitable for high-throughput testing -Spheroids produced are easily accessible | – Variability in cell size and shape if not as fixed cell no./well -DIY plate-coating is relatively labour intensive |

| hanging drop approach: supports cellular growth in suspension | -Inexpensive if using standard 96 well plate – Homogenous spheroids suitable for high-throughput testing -Spheroids produced are easily accessible | -More expensive if using specialised plates -Labour intensive if preparing plates in-house -Small culture volume makes medium exchange, without disturbing cells, difficult (proposed easier handling with commercially available formats) |

| agitation based approach: ancourage cells to adhere to each other to form 3D spheroid | – Simple to culture cells – Large-scale production relatively easily achievable – Motion of culture assists nutrient transport – Spheroids produced are easily accessible | – Specialised equipment required – No control over cell no./size of spheroid (can be overcome by additional culture step; see ‘Forced-floating methods’) – Time consuming for HTS due to extra step required for homogenous spheroids – Cells possibly exposed to shear force in spinner flasks (may be problematic for sensitive cells) |

Table 1. Proposed advantages and disadvantages of different 3D cell culture methods. Extracted and modified from Breslin and O’Driscoll, 2013, Drug Discovery Today.