The emergence of microfluidics has led to the integration of micro and nanofluidic devices in many applications such as biomedical and chemical analysis.

Micro and nanofluidic devices with very small channels (size in µm) offer interesting advantages in terms of reduced sample consumption and increased sensitivity thanks to the use of small volumes (micro/nano litter), which makes it possible to have a fairly large surface/volume ratio. The development of nanotechnologies and micro/nano-electromechanical systems (MEMS, NEMS) also makes it possible to manufacture and integrate microelectronic components very easily.

In this review, we will look at different methods to integrate pumps and valves on a microfluidic chip through various examples from the literature.

Fabrication of a PDMS Manual Micro-Valve System

Valves used in microfluidics are generally based on the following types of control structures : operating mechanics, pneumatics, electrokinetics, phase change, or introduction of external force.

There are two types of valves depending on their condition : active and passive valves. Their classification will then depend on their association with mechanical or non-mechanical moving parts.

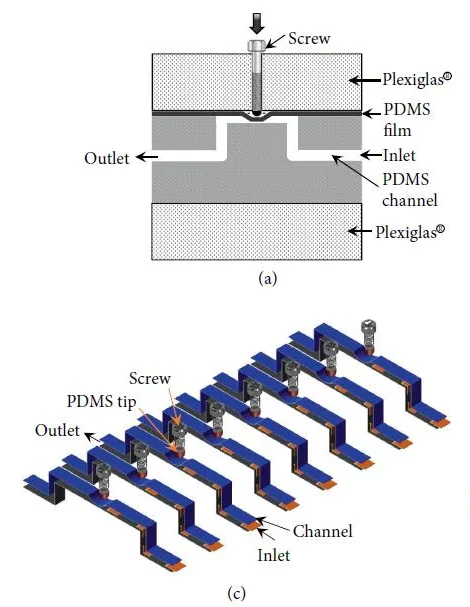

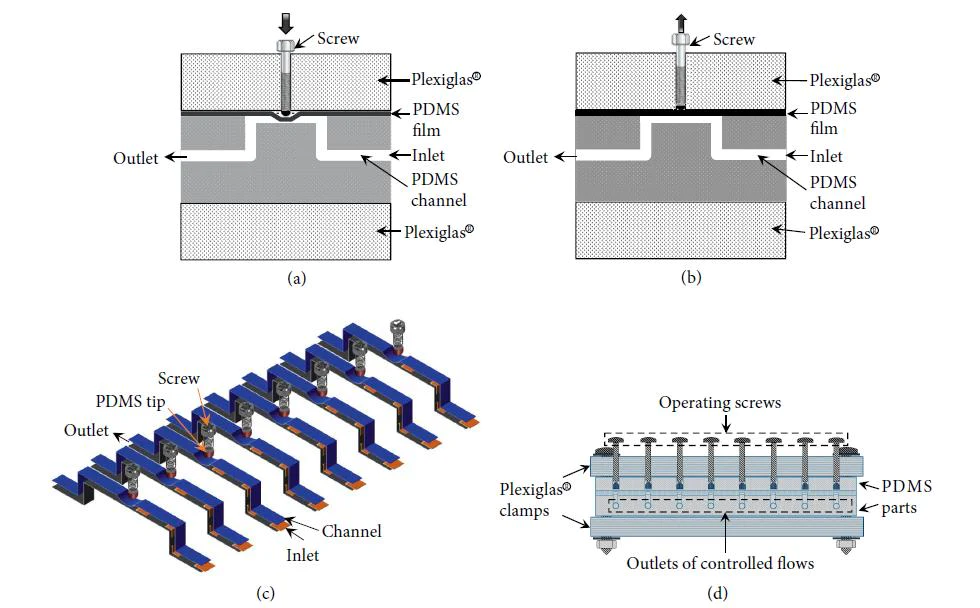

In this example, the researchers chose to manufacture their own valve. The operating principle of the valve is based on the mechanical structure (made of Plexiglas® materials) and flexible materials (PDMS) as described in figure 1.

The valve consists of an active part comprising a microchannel and a thin film made of PDMS (figures 1(a) and 1(b)). The PDMS film has been manufactured with a thickness of 100 µm and bonded to the top of the channel by means of functionalisation in a plasma cleaner. The microchannel was manufactured with the following dimensions of 1 × 0.05 × 10mm in PDMS by a soft lithography technique.

The mechanical structure for opening and closing the flow was combined with two components : a screw (~3 mm diameter, with a screw thread of 0.5 mm) is guided through a threaded hole in a Plexiglas slab, which in turn is fixed to a second slab ; a PDMS part (~2.5 mm) which is smaller than the screw hole and moves freely in this hole. The PDMS part helps the screw head not to crack the PDMS film during the working process.

Regarding the valve, there are two main structures comprising PDMS and Plexiglas® parts as shown in figure 1(d). The PDMS part contains the part with the channels (for channel valves) and an intermediate PDMS slab with several holes of the same diameter as the screws. Both mechanical structures have been manufactured from Plexiglas®, the first part of which has been designed with threaded holes, the second part is a lower support which, combined with the first part (like a clamp), allows all the elements of the structures of the valve system to be fixed.

To get more information about this design, we invite you to read the article Le T N et al. 2020, Adv. Polym. Technol.

We have to admit that this method is smart, practical and economical, but it cannot be applied in all cases, especially in regard to the presence of the screw. Indeed, some applications require very high integration and performance. We will therefore see in another example what is possible to do in prototyping.

Integrated heart/cancer on a chip to reproduce the side effects of anti-cancer drugs in vitro

For a long time, lab-on-a-chip has been used mainly for biochemical analysis and detection, but recently it has also been used for diagnosis.

Thus, progress towards a portable diagnostic system is becoming possible as technologies evolve. In addition to microfluidic systems, pumps, electrodes, valves, and electric fields are required. All of this can be done using integrated microelectronics.

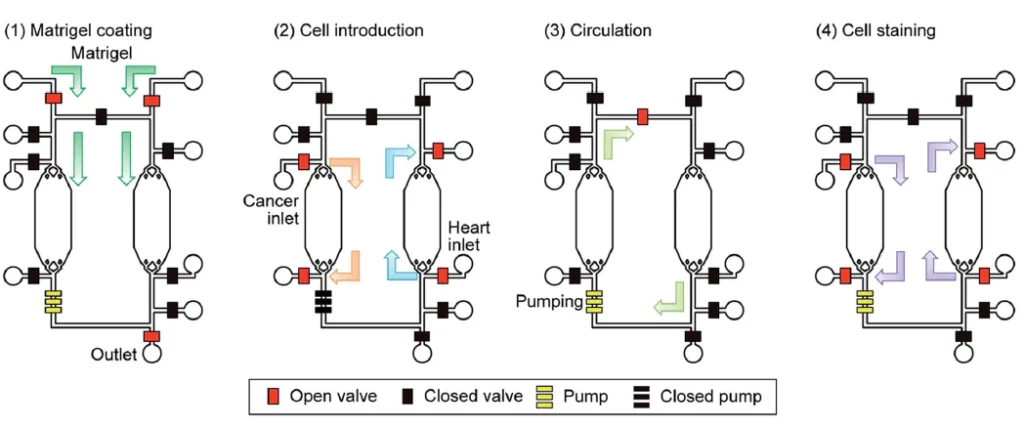

In this example, the team developed a microfluidic device—an Integrated Heart/Cancer on a Chip (iHCC)—using human healthy heart cells (hCMs) and liver cancer cells (HepG2) to recapitulate the side effects of an anti-cancer drug, doxorubicin (DXR), to achieve individual cultures of cells from different tissues on a single device with three sets of artificial blood circulation loops, microfabrication technology for micro valves and a pump provides accurate fluid operation.

For the manufacture of the iHCC, the team chose to use PDMS, in particular for its biocompatibility, good gas permeability and good light transparency.

The so-called infusion layer contains two cell culture chambers (2.1 mm wide and 220 mm high) which are sufficient to provide the necessary growth factors, the anti-cancer drug, and to reduce shear stress.

Micro-channels have been created to interconnect the two cell culture chambers (150 mm wide, 45 mm high) by inlet and outlet holes.

The so-called control layer, which is also made up of a thin and flexible PDMS membrane (200 x 200 µm² and 20 µm thickness), contains valves allowing the independent culture of two types of cells without cross-contamination as well as micropumps for precise control of the medium flow rate.

Thus, this device included three sets of two cell culture chambers with a closed circulation loop to allow three different but simultaneous cell treatments within the same device (Figure 2).

To get more information about this design, we invite you to read this article Kamei K et al 2017 RSC Adv.

Darwin Microfluidics has a wide range of microvalves and micropumps to make this kind of microfluidic prototype. Our experts have selected for you the products best suited to your application in the following table.

| Type of product | Size | Darwin Microfluidic website links |

| 2/2 or 3/2 Way Whisper Valve Type 6724 from Bürkert | 8.9 mm width | https://darwin-microfluidics.com/collections/microfluidic-valves/products/2-2-or-3-2-way-whisper-valve-type-6724 |

| 2/2 Way Microfluidic Whisper Valve Type 6712 from Bürkert | 18.2 x 7.2 x 7 mm | https://darwin-microfluidics.com/collections/microfluidic-valves/products/microfluidic-minimum-volume-solenoid-valve-burkert-type-6712 |

| 2/2 Way Microfluidic Miniature Valve from Memetis | 20 x 5 x 7 mm | https://darwin-microfluidics.com/collections/microfluidic-valves/products/2-2-way-microfluidic-miniature-valve |

| mp 6 serie micropumps from Bartels | 30 x 15 x 3.8 mm | https://darwin-microfluidics.com/products/bartels-mp6-micropump |

With this review, you have all the keys to get started in the manufacture of microfluidic prototypes. The experts at Darwin Microfluidics remains at your service to advise you!