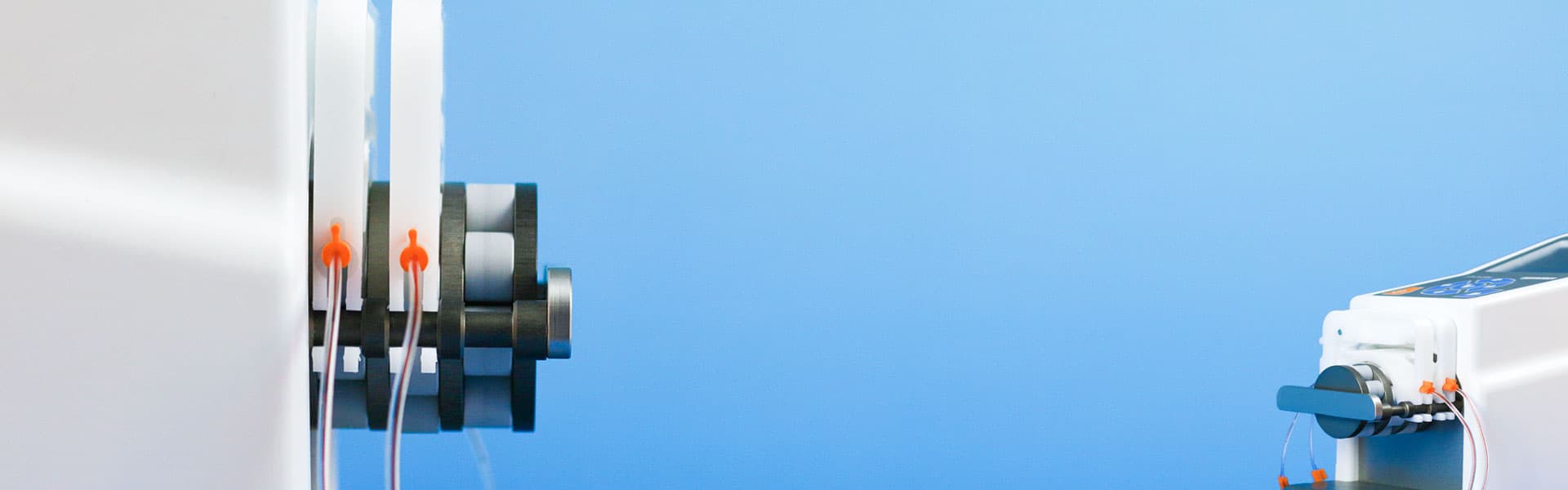

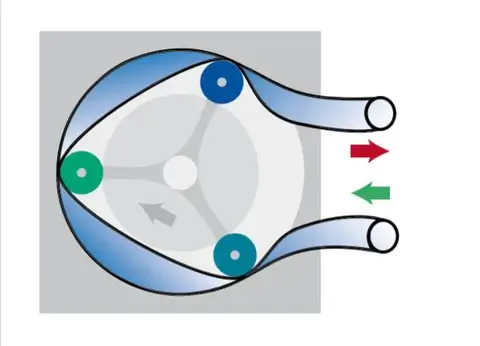

Functional principle of peristaltic pumps

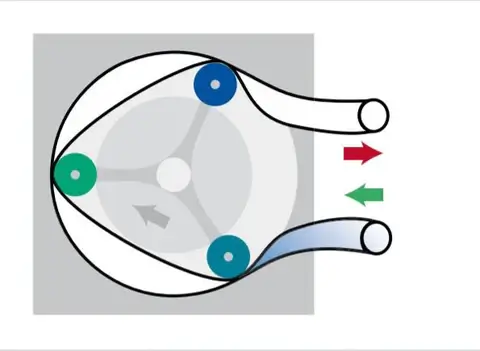

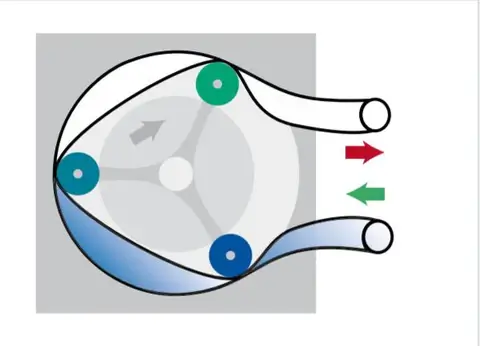

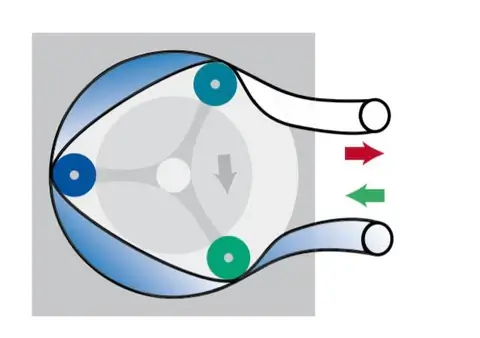

Peristaltic pumps are so-called roller pumps in which the rollers are rotated over a tube placed in the pump head, leading to the mechanical alteration of the form (squeezing) of the tube.

The restitution of the tube following the roller triggers the pumping of the medium in the interior of the tube so that only the pump tube comes into contact with the medium.

The flow rate is determined by the shape and the speed of the roller head, the number of rollers, and the inner diameter of the tube. Find our peristaltic pumps catalog here!

Pros and cons of peristaltic pumps for microfluidics

Pros

- Long term experiments are possible: the reservoirs are not closed and can be refilled while the pump is working.

- Robust and reliable: can work for weeks continuously.

- Easy recirculation setup: the outlet tubing can be in the same reservoir than the inlet tubing.

- Multichannel: you can extend the number of channels easily by changing the pump head. Generally, peristaltic pumps can be extended to up to 24 channels working at the same flow rate.

- Wide range of pumps and pump heads to accommodate the user’s requirements (tubing size, flow rate, environment…).

- Some peristaltic pumps have a dispensing feature, and can be programmed to dispense a certain volume based on time.

Cons

- Pulsatility: the peristaltism principle generates a more pulsatile flow than other technologies (syringe pumps, pressure controllers), while it is still stable on average. To compensate this pulsatility, more rollers can be added to the perisaltic pump head.

- Tubing wear: the pressure applied by the rollers to the peristaltic tubing leads to tubing deformation by the time. The lifetime for a standard silicone tubing is approx. 200 hours, while it is approx. 1000 hours for specialized peristaltic tubing.

- Flow rate: at low flow rates (below 10 µL/min), most of the peristaltic pumps are not accurate enough for microfluidic applications.

- All the channels in a peristaltic pump have the same flow rate. Only one peristaltic pump can drive up to 4 channels independently, the Reglo ICC from ISMATEC.