The use of microfluidics in biology and medicine offers exciting new possibilities for in-vitro cell culture thanks to increased control in the microenvironment of the cells.

Two important and connected topics emerging in this field are organ on chip and 3D cell culture. The powerful tools developed with the microfabrication of a wide range of polymer and non-polymer materials in microfluidics and micropatterning allow for a wide diversity in microenvironment engineering. This makes the development of in vitro models with unprecedented characteristics possible in any lab with cost and time-effective methods. Not only can the microenvironment be controlled efficiently, but the low volume of these models allows for efficient parallelization of in vitro studies lowering the cost and enabling higher throughput drug screening [1] [2].

A wide range of materials is available for researchers working or aiming at working in those fields with many different characteristics in biocompatibility, optical and mechanical properties, ease of handling, and cost. This review’s aim is to present materials used in microfluidic that can also be used for cell culture. We will shortly present their strength and weaknesses with respect to one another.

A large issue when going from conventional in-vitro to microfluidic cell culture is one of scale. Due to scale changes such as the volume to surface area in such culture devices, the characteristics of the cultured cells can be significantly altered. For instance, the ratio from the cell culture surface to media volume changes drastically from conventional cultures. [3]

Thermosets

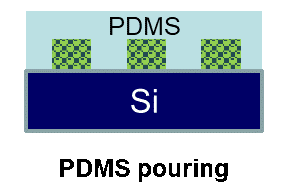

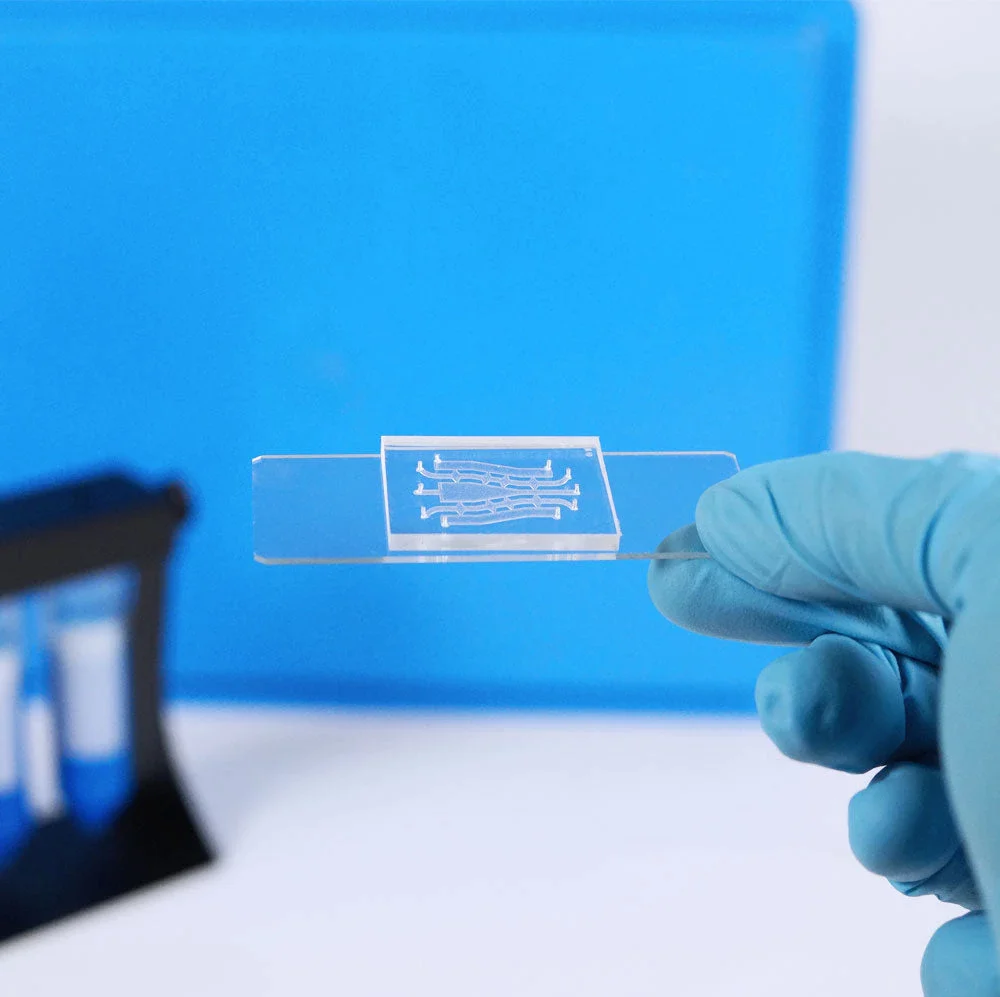

PDMS (polydiméthylsiloxane) is the material of choice for microfluidics, thanks mainly to the easy microfabrication process, its optical transparency, elastomeric properties, and the ability to be bonded permanently with glass or itself. These properties make PDMS wildly used for the microfabrication of microfluidic devices at a lab scale.

In cell culture, the biocompatibility and the gas permeability of PDMS make it adapted to cell culture in microchannels. Its optical properties combined with low autofluorescence make it ideal for fluorescence detection and it can be molded and bonded without a clean room making it attractive for research teams looking to begin in microfluidics.

However, PDMS does have some drawbacks, especially when it comes to the absorption of small molecules. This can be especially critical in cell culture for drug testing as the PDMS can alter significantly the concentrations of species of interest, which can be critical when monitoring nano and micromolar concentrations.[4]

PDMS is also permeable to water vapor so the device may dry or have unstable channel osmotic concentration.

These properties can make the use of PDMS quite complex for longer experiments. Nonetheless, the material has been a staple of microfluidics for a long time and the large body of literature already covering the subject

Thermoplastic polymers for cell culture

Thermoplastic polymers such as polycarbonate and polystyrene are another type of material used in microfluidics that has also seen use in cell culture. The microfabrication process is fast and going from the base material to a functional chip can be done in minutes and can accommodate any scale, from prototyping to industrialization.

They usually have rigid interfaces, making the bonding process harder than with PDMS. Nonetheless, the wide variety of thermoplastics makes them promising for future application development as it is possible to find one with characteristics fitting the application and they all require the same production process only slightly tweaked.

Some of the thermoplastics used in microfluidic and for cell culture are :

Polystyrene (PS) and cyclo-olefin polymer (COP)[5] have been shown to be suitable for cell culture while alleviating the absorption of small hydrophobic molecules and release of an uncrosslinked oligomers that are present with PDMS.

Cyclo-olefin copolymer (COC)[6] [7] [8] are a category of COP made with multiple kinds of monomers. Some variants have high biological inertness and are suitable for cell culture after an air-plasma treatment for HeLa cells. [9]

Polymethyl-methacrylate (PMMA) is a thermoplastic that can not only be hot-embossed, but also laser etched, reducing the number of components needed for the microfabrication process. [10] [11] [12]

Polycarbonate (PC) is already a widely used material for cell culture, it has also been used with microfluidics. However, the closed nature of the channels with the non-permeable nature of the material makes it non ideal with the specific constraints of microfluidics. PC is therefore often used in conjunction with PDMS in hybrid chips to produce oxygen gradients thanks to the low oxygen permeability. [13]

Thermoplastics like COC, PMMA and PC have been shown to exhibit significantly more autofluorescence than PDMS making them unsuitable for certain detection methods. [14]

Soft thermoplastic elastomer

The use of elastomeric soft materials is of great interest for microfluidics as a whole. The low rigidity of such material makes them sufficiently deformable for the direct fabrication of embedded mechanical elements such as micropumps and valves. This makes complex functions far easier to implement in elastomeric materials like PDMS. Another category of elastomeric materials is soft thermoplastic elastomers (sTPE). They are block copolymers comprising of an elastomeric matrix with hard thermoplastic domains comprised of multiple blocks small enough to be continuous at the microdevice scale (µm). This gives chemical properties and an easy molding process close to hard thermoplastics with the elastomeric properties allowing for easy bonding and micromechanical features.

Flexdym[15] is a sTPE developed to alleviate PDMS drawbacks in microfluidics with regards to quick prototyping, adsorption, absorption and substrate bonding while keeping the advantages like softness, optical properties, biocompatibility and gas permeability. It can be used for cell culture thanks to it’s gas permeability (although it is lower than in PDMS) and the prototyping can be extremely quick, taking only minutes to go from the molding process to the final sealed chip. It can also be injected meaning that scaling up to an industrial scale is straightforward.

Perfluoropolyethers (PFPE) [16] have been utilized for cell culture and show performance similar to PDMS chips mainly thanks to their gas permeability. PFPE are soft and transparent, making them very similar to PDMS. They can be patterned directly by photolithography which is a significant advantage as it eliminates the need for a mold and reduces the number of steps for microchip production. However, some drawbacks are the high cost and the really high chemical inertness of the material making surface modification difficult.

Glass [17] has some really interesting properties for microfluidic cell culture, especially its chemical stability and optical properties can be used for increased measurement repeatability. However, complex and costly production makes it a niche material for research and industry alike. Glass stays a premium material for prototyping, but the versatility of surface treatments available to it and its resistance can make up for the higher cost, especially for reusable chips.

Paper-based microfluidics is a recent development for the production of low-cost point of care applications. The impression of culture microreactors onto paper by modifying the surface to enhance cellular adhesion is particularly promising for future low cost cell detection diagnostics. [18]

[1] Su, X., Young, E. W., Underkofler, H. A., Kamp, T. J., January, C. T., & Beebe, D. J. (2011). Microfluidic cell culture and its application in high-throughput drug screening: cardiotoxicity assay for hERG channels. Journal of biomolecular screening, 16(1), 101-111.

[2] An, D., Kim, K., & Kim, J. (2014). Microfluidic system based high throughput drug screening system for curcumin/TRAIL combinational chemotherapy in human prostate cancer PC3 cells. Biomolecules & therapeutics, 22(4), 355-362.

[3] Walker, G. M., Zeringue, H. C., & Beebe, D. J. (2004). Microenvironment design considerations for cellular scale studies. Lab on a Chip, 4(2), 91-97.

[4] Toepke, M. W., & Beebe, D. J. (2006). PDMS absorption of small molecules and consequences in microfluidic applications. Lab on a Chip, 6(12), 1484-1486.

[5] Su, X., Young, E. W., Underkofler, H. A., Kamp, T. J., January, C. T., & Beebe, D. J. (2011). Microfluidic cell culture and its application in high-throughput drug screening: cardiotoxicity assay for hERG channels. Journal of biomolecular screening, 16(1), 101-111.

[6] Mottet, G., Perez-Toralla, K., Tulukcuoglu, E., Bidard, F. C., Pierga, J. Y., Draskovic, I., … & Louis Viovy, J. (2014). A three dimensional thermoplastic microfluidic chip for robust cell capture and high resolution imaging. Biomicrofluidics, 8(2), 024109.

[7] Jena, R. K., & Yue, C. Y. (2012). Cyclic olefin copolymer based microfluidic devices for biochip applications: Ultraviolet surface grafting using 2-methacryloyloxyethyl phosphorylcholine. Biomicrofluidics, 6(1), 012822.

[8] Nunes, P. S., Ohlsson, P. D., Ordeig, O., & Kutter, J. P. (2010). Cyclic olefin polymers: emerging materials for lab-on-a-chip applications. Microfluidics and nanofluidics, 9(2-3), 145-161.

[9] Johansson, B. L., Larsson, A., Ocklind, A., & Öhrlund, Å. (2002). Characterization of air plasma‐treated polymer surfaces by ESCA and contact angle measurements for optimization of surface stability and cell growth. Journal of applied polymer science, 86(10), 2618-2625.

[10] Hong, T. F., Ju, W. J., Wu, M. C., Tai, C. H., Tsai, C. H., & Fu, L. M. (2010). Rapid prototyping of PMMA microfluidic chips utilizing a CO2 laser. Microfluidics and nanofluidics, 9(6), 1125-1133.

[11] Wei, C. W., Cheng, J. Y., & Young, T. H. (2006). Elucidating in vitro cell-cell interaction using a microfluidic coculture system. Biomedical microdevices, 8(1), 65-71.

[12] Ma, L., Zhou, C., Lin, B., & Li, W. (2010). A porous 3D cell culture micro device for cell migration study. Biomedical microdevices, 12(4), 753-760.

[13] Chang, C. W., Cheng, Y. J., Tu, M., Chen, Y. H., Peng, C. C., Liao, W. H., & Tung, Y. C. (2014). A polydimethylsiloxane–polycarbonate hybrid microfluidic device capable of generating perpendicular chemical and oxygen gradients for cell culture studies. Lab on a Chip, 14(19), 3762-3772.

[14] Piruska, A., Nikcevic, I., Lee, S. H., Ahn, C., Heineman, W. R., Limbach, P. A., & Seliskar, C. J. (2005). The autofluorescence of plastic materials and chips measured under laser irradiation. Lab on a Chip, 5(12), 1348-1354.

[15] Roy, E., Stewart, G., Mounier, M., Malic, L., Peytavi, R., Clime, L., … & Veres, T. (2015). From cellular lysis to microarray detection, an integrated thermoplastic elastomer (TPE) point of care Lab on a Disc. Lab on a Chip, 15(2), 406-416.

[16] Jellali, R., Paullier, P., Fleury, M. J., & Leclerc, E. (2016). Liver and kidney cells cultures in a new perfluoropolyether biochip. Sensors and Actuators B: Chemical, 229, 396-407.

[17] Jang, K., Sato, K., Igawa, K., Chung, U. I., & Kitamori, T. (2008). Development of an osteoblast-based 3D continuous-perfusion microfluidic system for drug screening. Analytical and bioanalytical chemistry, 390(3), 825-832.

[18] Corradini, E., Curti, P. S., Meniqueti, A. B., Martins, A. F., Rubira, A. F., & Muniz, E. C. (2014). Recent advances in food-packing, pharmaceutical and biomedical applications of zein and zein-based materials. International journal of molecular sciences, 15(12), 22438-22470.